FPRDI’s fiber analysis helps specialty paper industry

|

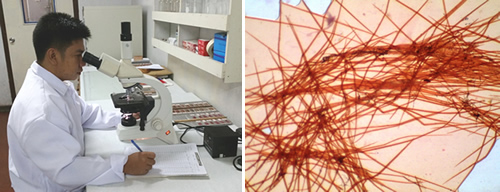

FPRDI’s Emmanuel P. Domingo (left) peers into a microscope to measure the different plant fibers (right) used by the Specialty Pulp Manufacturing, Inc. based in Quezon City.

“Studying the form and shape of natural fibers allows us to see whether or not they are fit for specific end-uses,” says Domingo.

“For instance, if a company wants to know if its fiber sample is appropriate for durable handmade paper, we have to check if the fibers are long enough because long fibers mean strong paper. We also measure the fibers’ diameter and the thickness of their cell walls to see how slender, flexible and dense they are.”

“The service we give to clients like the SPMI is critical,” claims Domingo, “as it helps ensure that the quality of their raw materials are at par with international standards.”

SPMI produces and exports food grade and non-food grade bleached and unbleached specialty pulp, mainly from abaca and other natural long fibers such as sisal, kenaf and jute.

These serve as raw materials for the production of high quality specialty papers such as currency and security paper, teabag paper, coffee filter, meat and sausage casing, filter paper, plug wrap, cigarette paper, stencil paper and electrolytic condenser paper. (Rizalina K. Araral, 20 October 2014)#