Musical instrument maker commends DOST-FPRDI

- Details

Nine years into making musical instruments, Jay Sarita is still looking for ways to improve his craft.

The owner of the Dipolog-based Sarita Instrument Artisan and a Master Teacher at the Dipolog Pilot Demonstration School, Sarita has commercially produced traditional rondalla instruments, including banduria, octavina, laud and base guitars. He has also made bamboo musical instruments (BMI) such gabbang, angklung and xylophones.

“My interest in music led me to become an instrument-maker and music teacher. Instrument- making was all trial and error for me, until I met Dr. Wu Shih-Yin, a retired professor and consultant of the Taiwan Bamboo Orchestra. He taught me how to speed up my production process using science-based procedures,” Sarita shared.

DOST-FPRDI holds 1st virtual Technology Forum

- Details

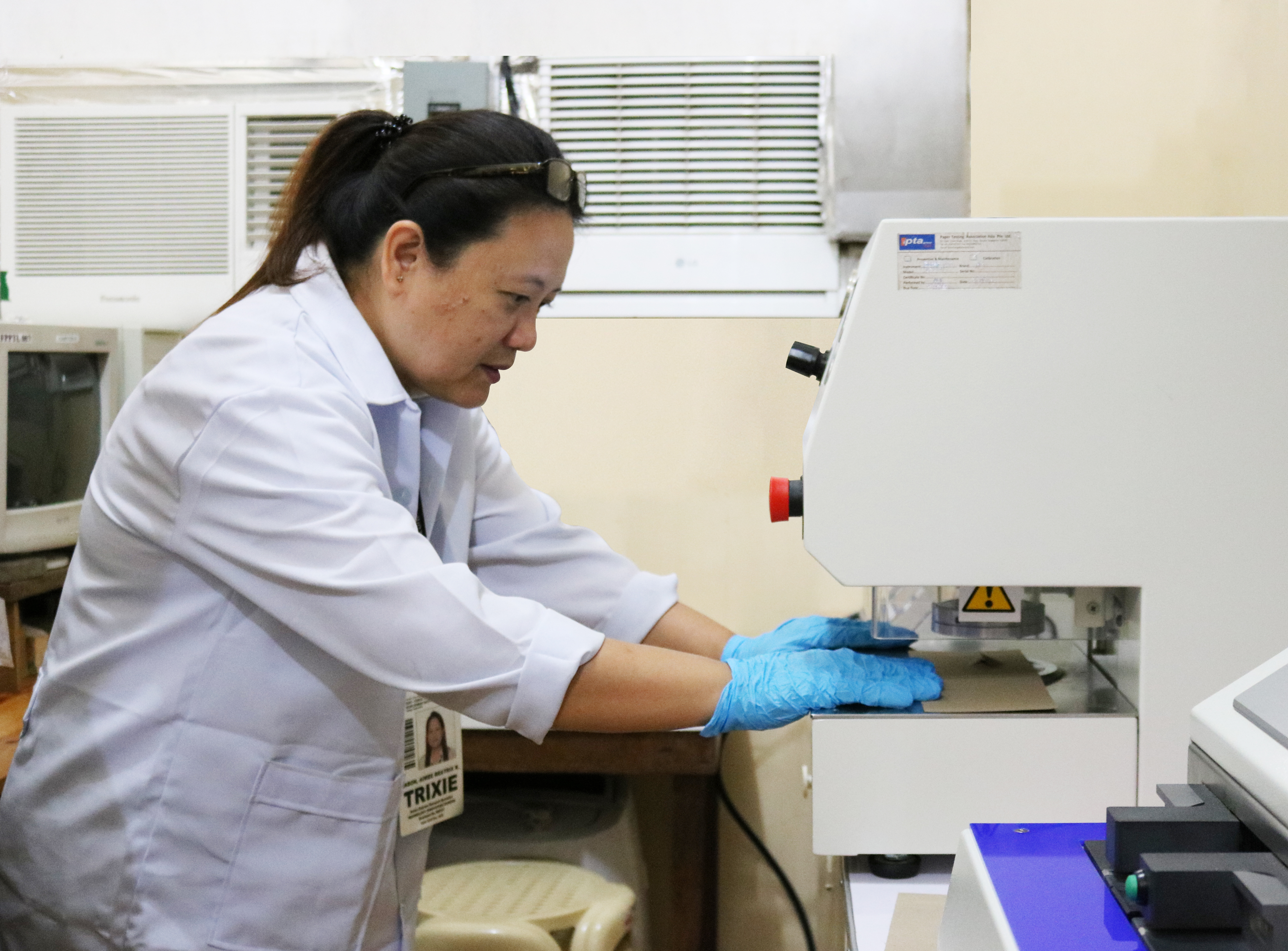

The DOST-Forest Products Research and Development Institute (DOST-FPRDI) recently conducted an online Technology Forum that offered livelihood ideas for small entrepreneurs.

The forum covered five most currently in-demand technologies of the Institute: charcoal briquetting; handmade paper and fossilized leaves making; bamboo-framed retractable face shields production; and personal hygiene anti-microbial products making. Resource persons were Engr. Amando Allan M. Bondad, For. Sheena Kryzel F. Siapno, Engr. Cesar O. Austria and Dr. Jennifer P. Tamayo.

DOST-FPRDI: Abaca hybrid yields quality fiber

- Details

Brighter days may be up ahead for the country’s abaca industry. Researchers at the Department of Science and Technology’s Forest Products Research and Development Institute (DOST-FPRDI) have recently found that the “Bandala” abaca hybrid yields high quality fiber that makes it a promising material for pulp and paper.