DOST-FPRDI joins 19th International Botanical Congress

- Details

|

For. Jennifer M. Conda of the DOST’s Forest Products Research and Development Institute (DOST-FPRDI) recently joined other botanists and plant scientists in the largest global conference on the plant sciences.

DOST-FPRDI boosts help to indigenous groups

- Details

In support of the Duterte administration’s socio-economic agenda that underpin rural development, the Department of Science and Technology’s Forest Products Research and Development Institute (DOST-FPRDI) has intensified its technology assistance particularly to the country’s tribal community.

Last July 18-20, 2017, FPRDI’s Training and Manpower Development Services Section (TMDSS) held a lecture-demo on some bamboo processing technologies for Batak Craft — a livelihood development project for the Batak tribe in Palawan.

Led by its founder Ms. Lara Frayre, Batak Craft sought FPRDI’s help in improving handcrafted baskets made mainly from “buho” bamboo. Among the topics covered were bamboo preservation, drying, handicraft making and finishing.

According to Ms. Frayre, their long-term plan is to develop a sustainable livelihood for the indigenous tribe and to set up a bamboo craft industry in Puerto Princesa, Palawan. As of now, Batak Craft is exploring ways on how best to utilize buho, which abounds in Batak communities.

DOST-FPRDI wood ID team supports preservation of century-old building in Iloilo City

- Details

|

| Facade of the century-old Commission on Audit (COA) Building in Iloilo City. |

|

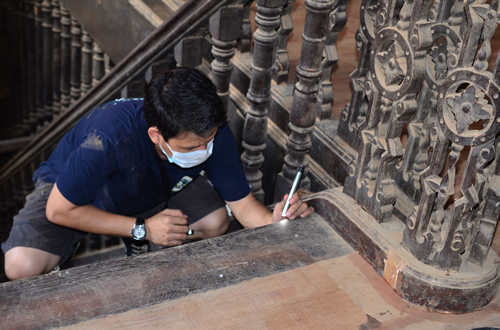

| For. Mario DR. Ramos examines and identifies the wood used for a stair step using flashlight and a hand lens. |