DOST-FPRDI leads abaca R&D program

- Details

DOST-FPRDI leads abaca R&D program

January 12, 2015

The Philippines is the world’s number one producer of abaca, known as the strongestamong the natural fibers. Ironically, however, we buy most of our processed abaca-based high-end products from other countries, including those that get their raw material from us.

“This is a situation we want to change,” disclosed Dr. Erlinda L. Mari, Scientist I of the Forest Products Research and Development Institute (FPRDI), an agency of the Department of Science and Technology (DOST) based in Los Banos, Laguna.

“Thru aresponsive R&D program that it has recently initiated, FPRDI will help push for the optimum use of our abaca resources to benefitthe local pulp and paper industry, the abaca sector, and other related industries.”

FPRDI’s wood ID assists archaeologists

- Details

FPRDI’s wood ID assists archaeologists

For 54 years now, FPRDI - thru its wood identification service – has been helping both local and foreign archaeologists in establishing the identity of wood specimens recovered from their study sites.

Explains wood anatomist Dr. Ramiro P. Escobin, “Our clients are mostly researchers from the National Museum and the University of the Philippines Archaeological Studies Program who bring to us for identification either charred, desiccated or waterlogged wooden artifacts.”

He relates, “The oldest wood specimen I have examined was an 800,000-year-old sample from Cagayan Valley submitted by a French researcher, while the most recent were the remains of a Spanish galleon ship.”

FPRDI’s fiber analysis helps specialty paper industry

- Details

FPRDI’s fiber analysis helps specialty paper industry

|

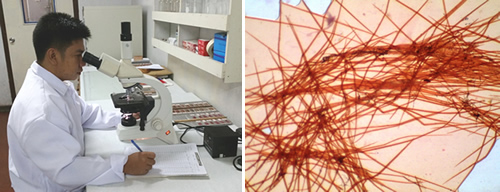

FPRDI’s Emmanuel P. Domingo (left) peers into a microscope to measure the different plant fibers (right) used by the Specialty Pulp Manufacturing, Inc. based in Quezon City.